One of the most frequent questions that customer and reps ask us is “Can you model this?” Even though the answer is always a resounding yes – we love a challenge – every rep and customer is still surprised at the broad array of applications that benefit from a Computational Fluid Dynamics (CFD) analysis. This means that a myriad of designs currently in use in different sectors of the building industry could have been improved.

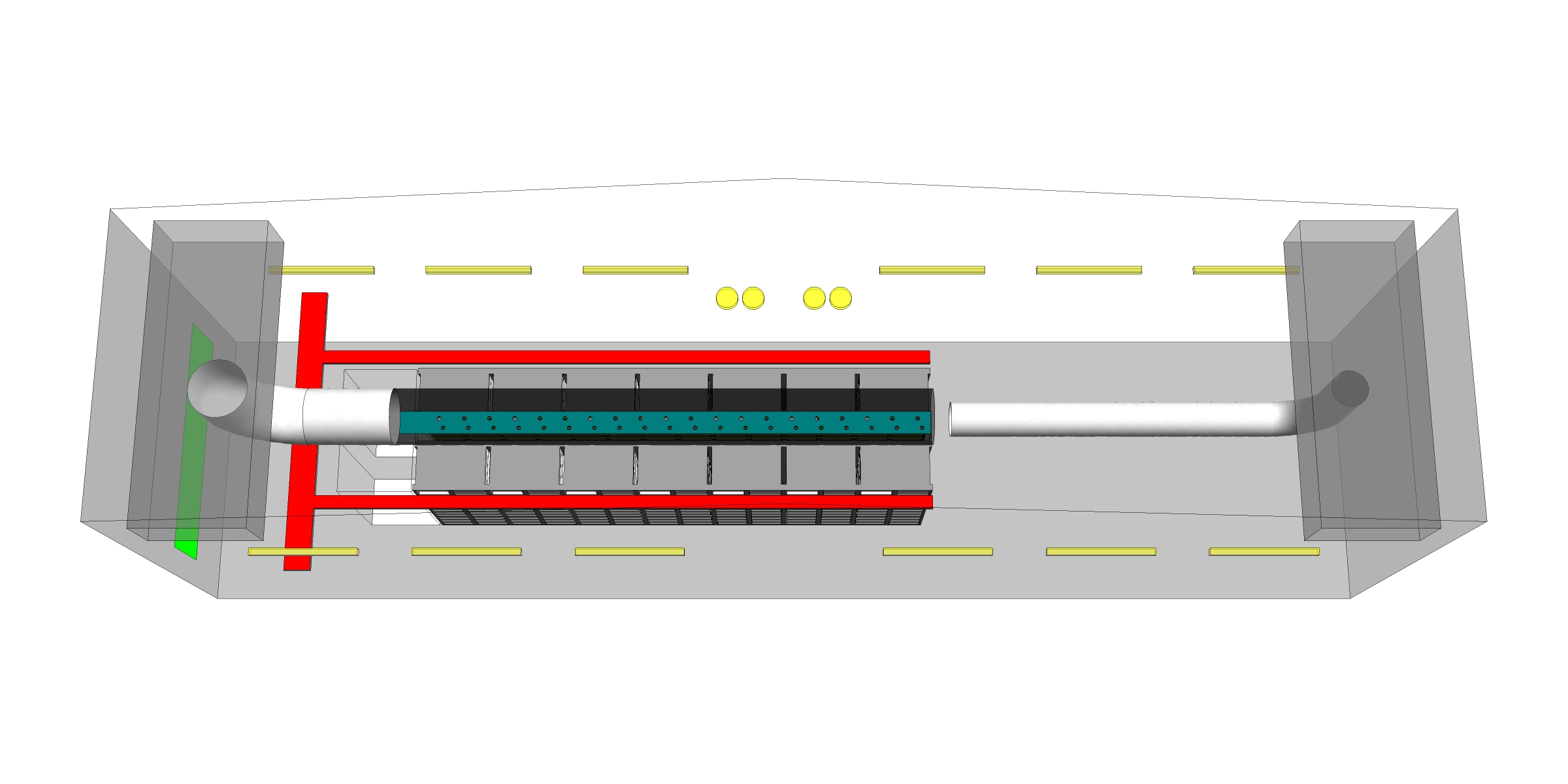

In the summer of 2019, the Price Predict team was commissioned to do a CFD analysis on a project involving a battery energy storage system (BESS). A BESS is a large bank of rechargeable batteries with capacities in the megawatt-hour range that are integrated into an electrical grid and store power for later use. This system can be used either to balance and store electricity generated from fluctuating renewable sources, such as wind and solar power, or to increase the reliability of existing distribution systems by maintaining a steady supply of power when the main grid is down.

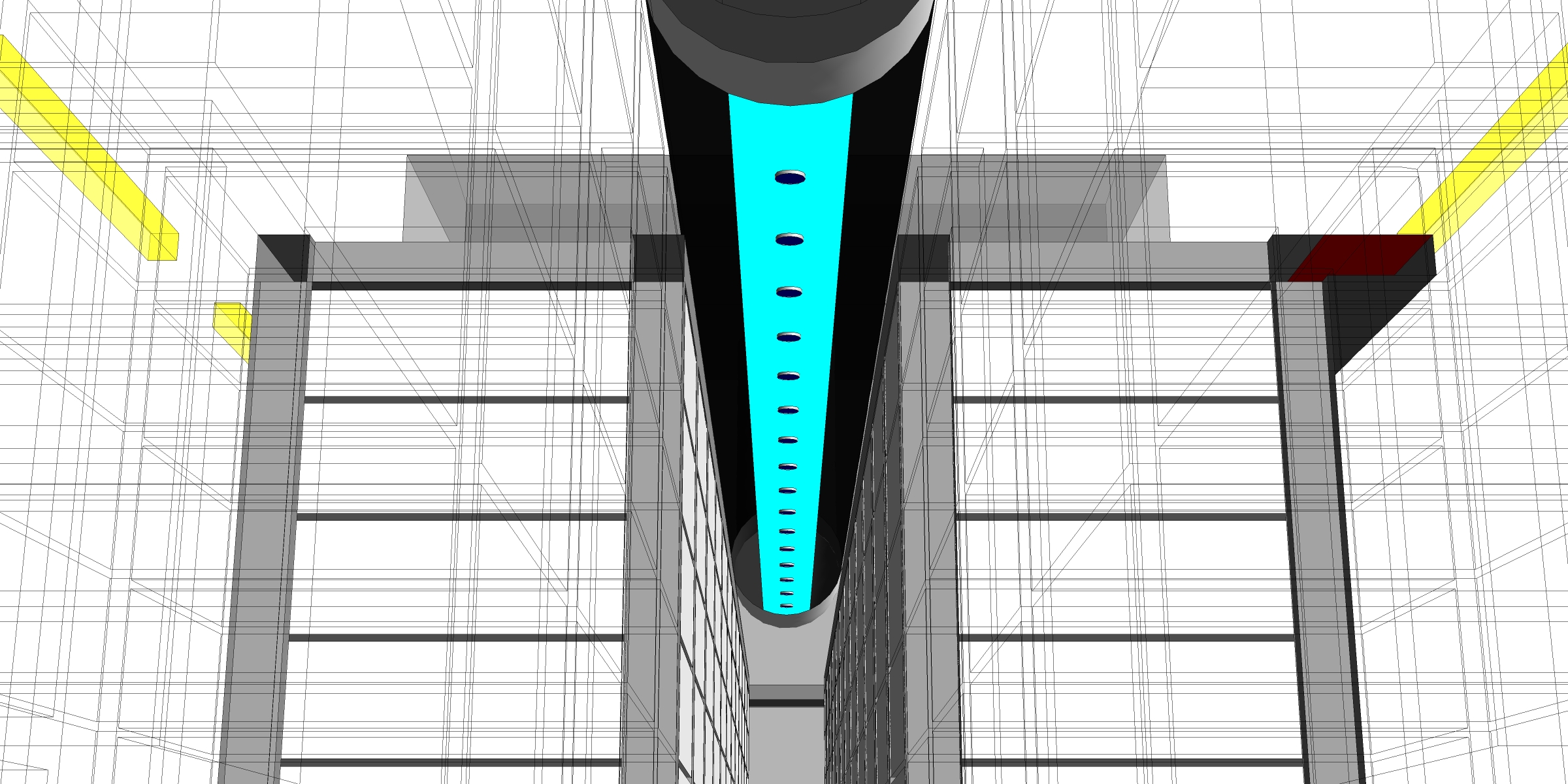

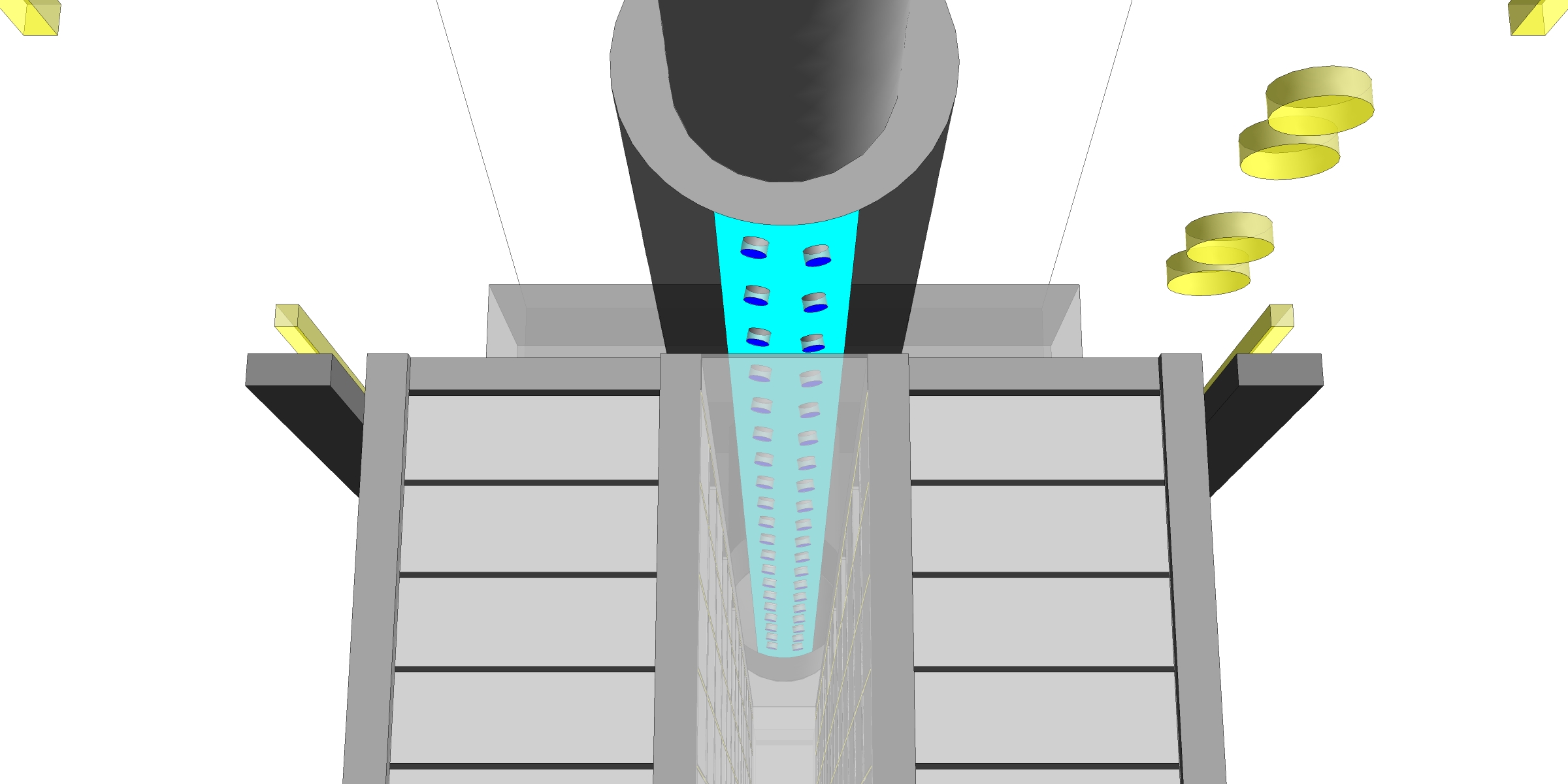

The batteries in a BESS generate heat when they are charged and discharged and, therefore, require a cooling system to keep them at an optimal operating temperature. To maximize the storage capacity of a BESS, densely packed banks of batteries are used, which yield heat gains of around 100 BTUH/sq. ft. By comparison, a typical North American office has a thermal load density of 10 to 20 BTUH/sq. ft., while a data center would be around 160 BTUH/sq. ft. Tightly packed arrays of batteries and large thermal loads mean that effectively cooling a BESS can be very challenging.

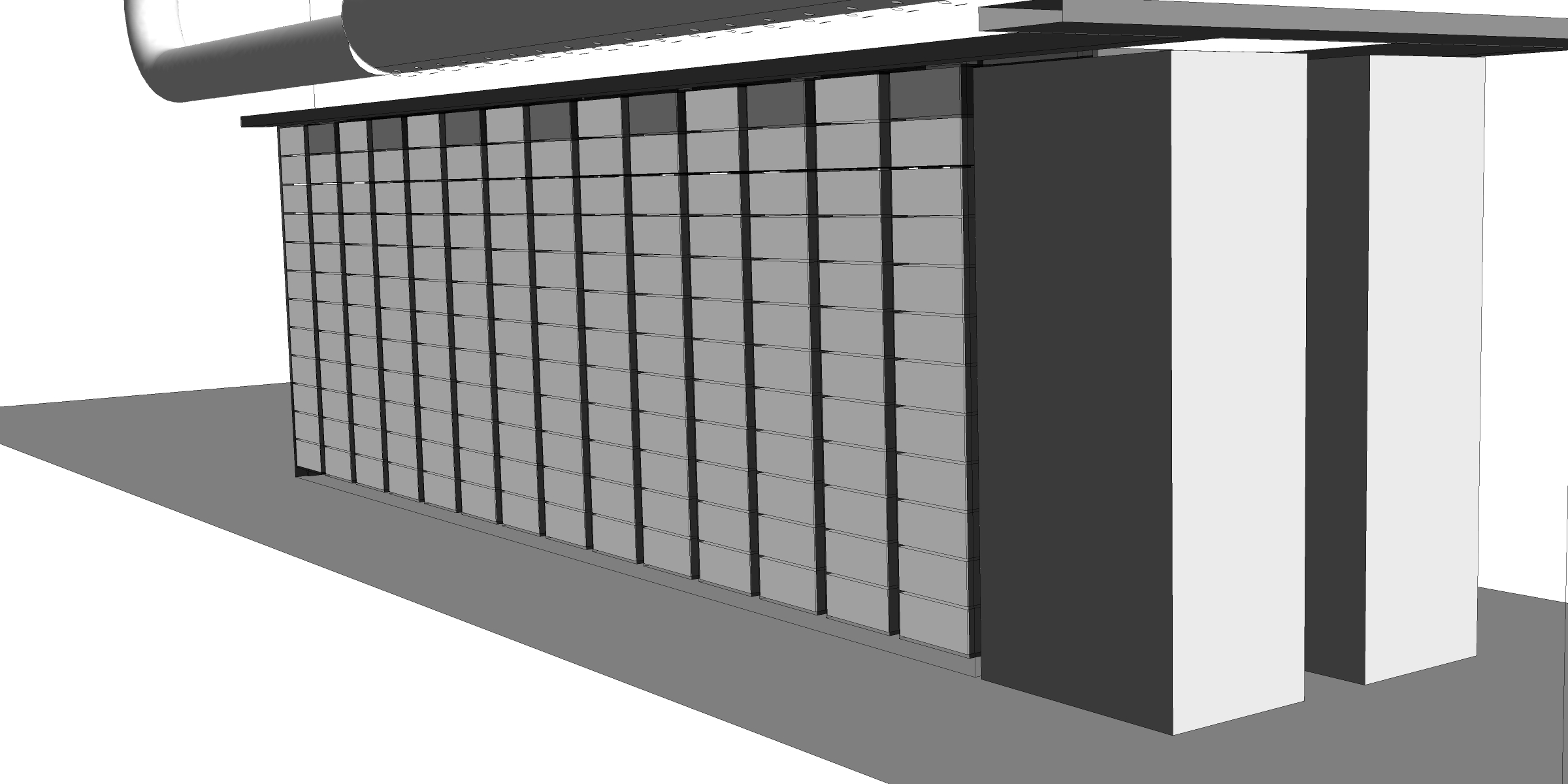

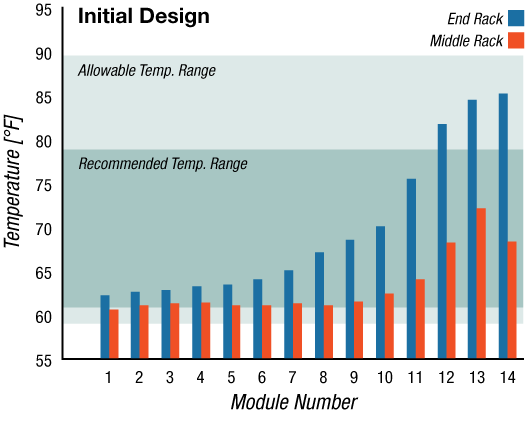

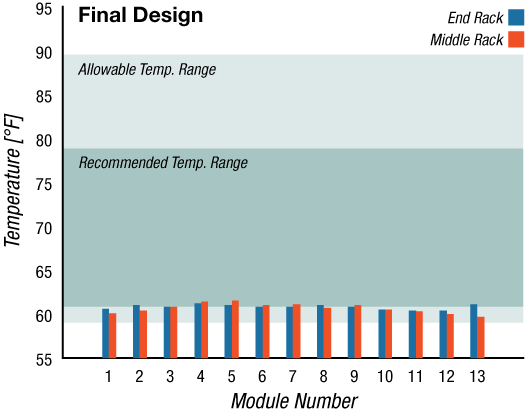

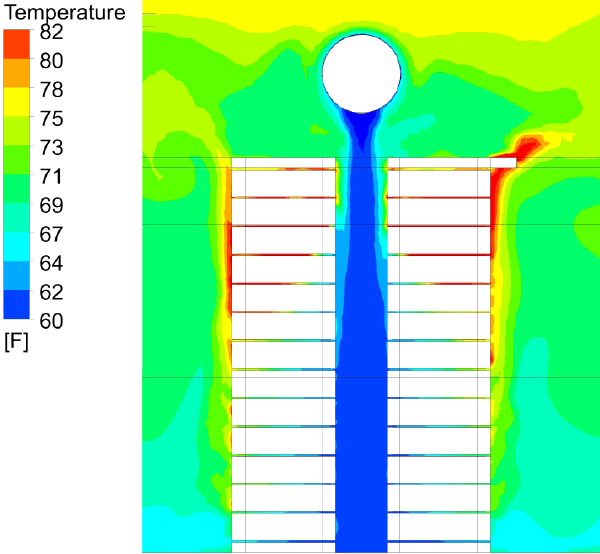

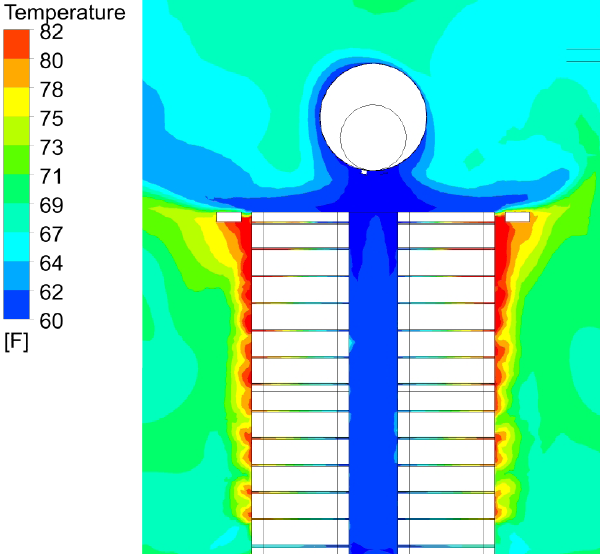

The Bulwer BESS project in downtown Toronto, ON, is an 8MWh facility built for Toronto Hydro and funded by the Ontario Smart Grid Fund. Madonna Engineering, a local firm, was responsible for designing the HVAC system. The firm engaged the Predict team to help optimize the cooling and air distribution within this facility by leveraging the power of CFD.